In the summer of 2017 we began our journey to build an electric racecar to compete in the 2018 Lincoln Nebraska Formula SAE Competition. This was the 5th electric race car build in the UC Davis formula racing team’s history. We had placed 6th place overall in the previous years competition and were ready to break that record and take 1st place with our new race car. We set out with one global target across all subteams, to reduce weight of the overall vehicle.

Being the drivetrain team leader I was very familiar with where the previous years’ car fell short. Therefore I came up with a set of goals for FE5’s drivetrain which were:

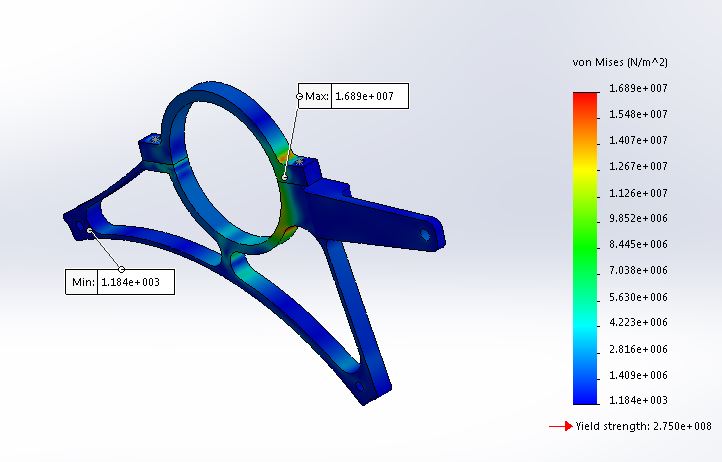

- Reduce overall system weight

- Eliminate flex in the system

- Increase ease of assembly and adjustment

- Use the optimal gear ratio for quickest lap times

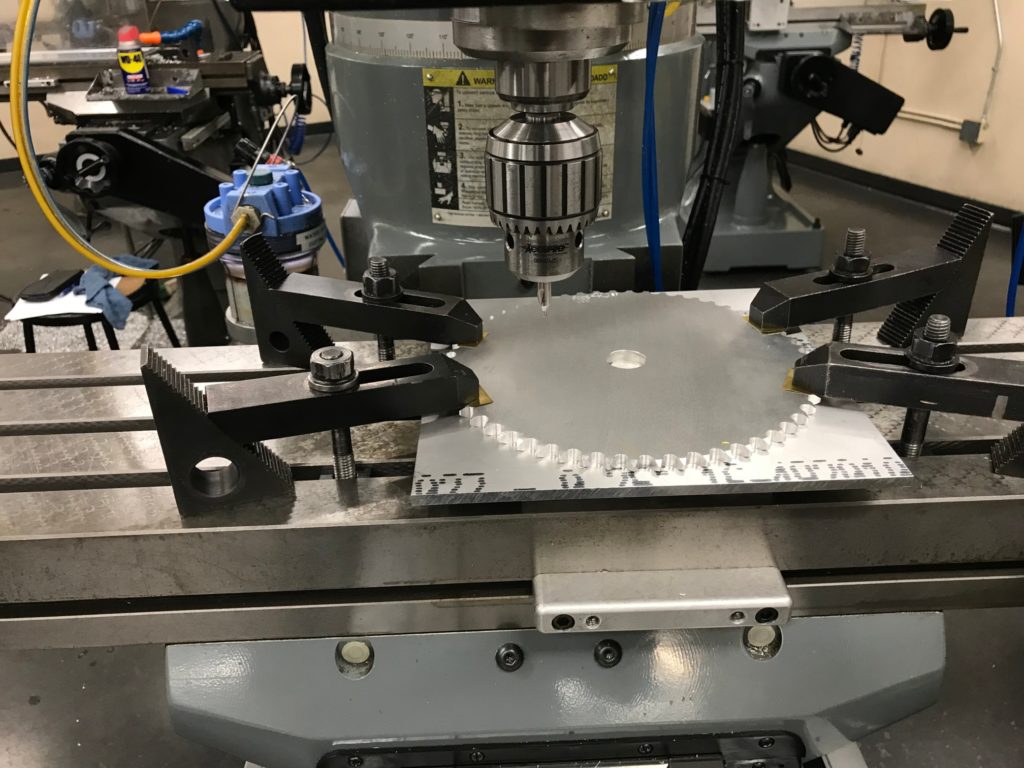

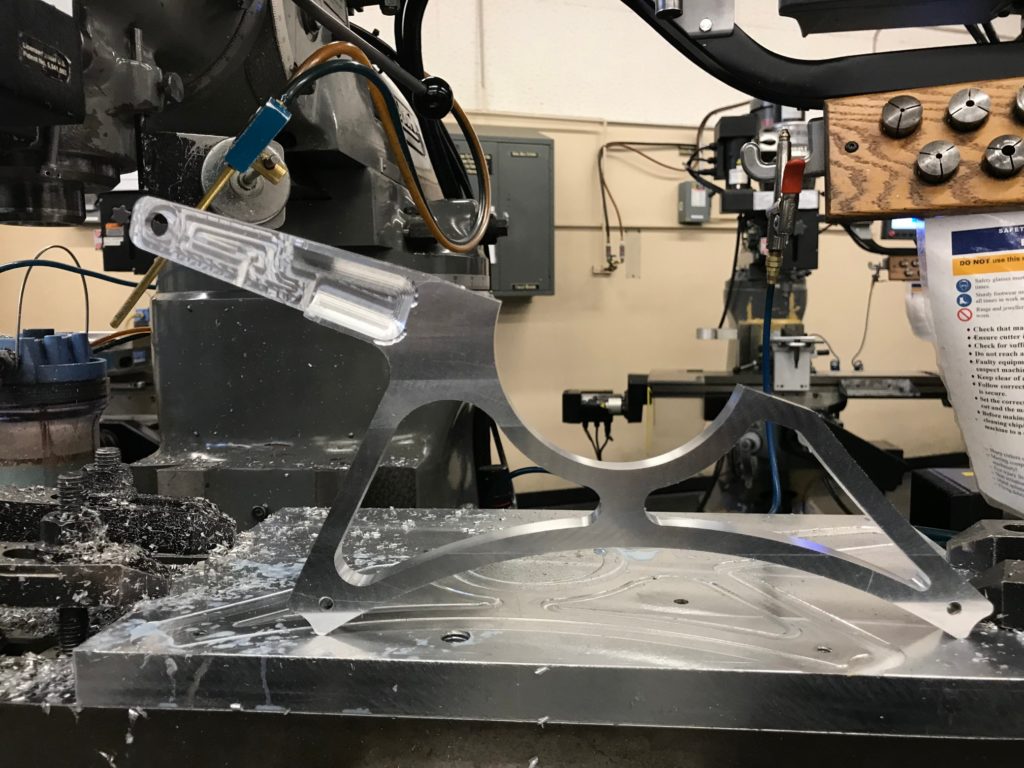

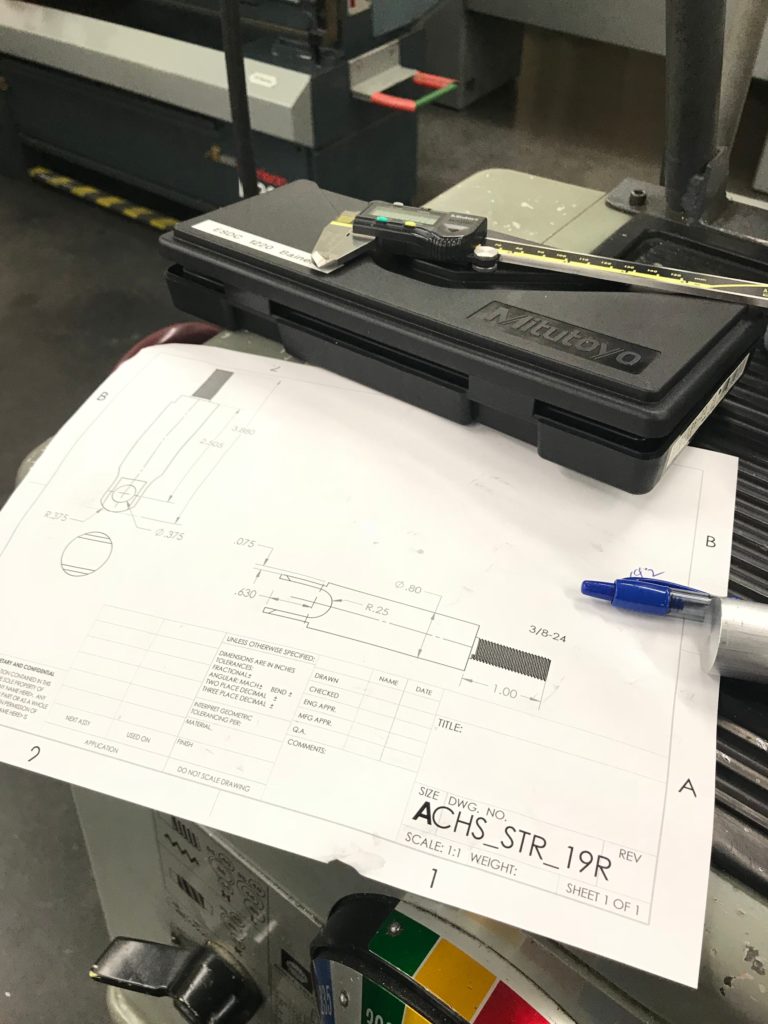

The previous years vehicle was already very light so it was a difficult task to reduce weight while retaining strength and stiffness of the system. Using SolidWorks we were able to design a drivetrain which weighed 1.21 lbs less than the previous years and was stiffer and stronger in all aspects. This whole build required constant reiterations of design in order to fit tight packaging requirements and constant communication between all subteams. After the design phase we manufactured all parts for the drivetrain using CNC and manual mills and lathes. After which we had a brief test season and we were off to competition. Where we received 1st place in cost by producing the cheapest vehicle.